Italy

Italy

3-roll

Bending capacity:

Plate width: 3000 mm

Plate thickness 140 mm

Thickness max 200 mm depending on plate width and yield strength

Technical data:

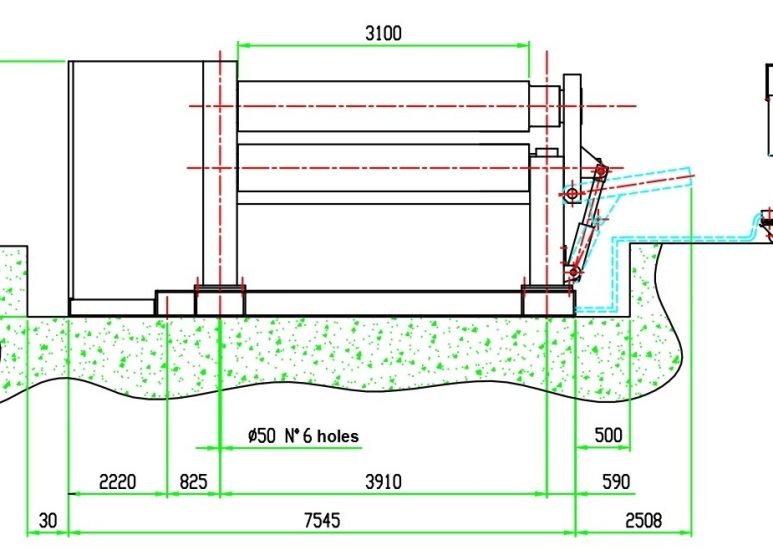

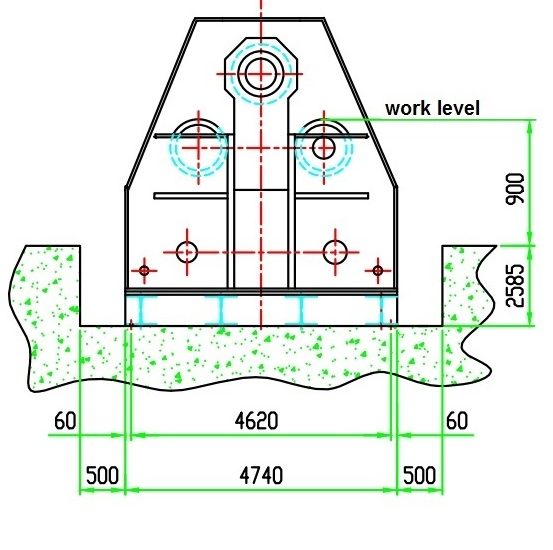

3100 mm Surface useful length on rolls

940 mm size of Top roll

840 mm size of Lower rolls

210 mm max thickness opening between the rolls

400/50 Vac voltage – rewirable 480/60

220 Hp Power electric installed

Configuration installed with the machine

Hardened surface of the 3 rolls.

Conical plate bending hydraulic attachment with hardened contrast pad.

All the 3 rolls driven with axial gearbox and motor each roll independent

Calibration system for the re-rolling of welded shells rounding unwanted flat spots.

Console electric on wheels with centralized commands joysticks and digital readout.

Opening front side hydraulic drop-end to unload closed shells.

Variable speed working slow/fast.

Emergency systems all installed in compliance with mc tools safety regulation.

Machine predisposed to take installation of extra tooling all circuitry onboard ready to connect.

1x top support ID max 5mtrs 10Ton 1 x side 10Ton support dual articulation for large ID

Hardened surface of the 3 rolls.